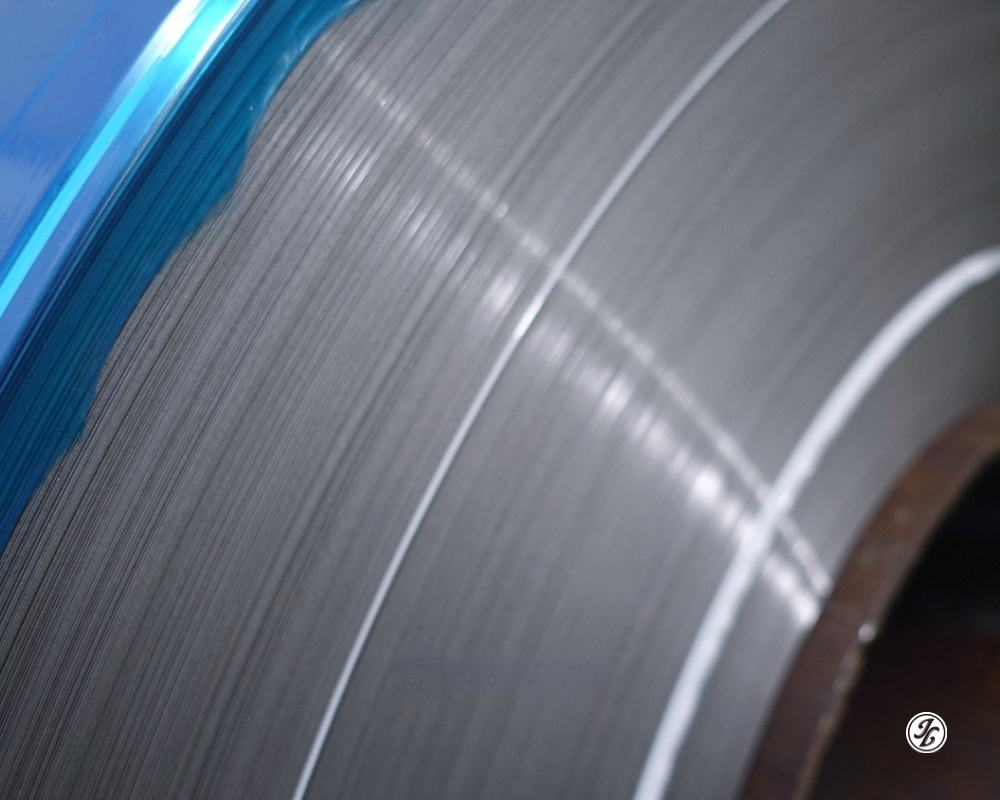

Cold-Rolled Stainless Steel Coils and Sheets

Basically, Jinling Steel stocks the most common and widely-accepted grades of stainless steel, such as stainless steel 304,304L,316L,201-J series,430,410S,409L,439.

Product Details

Download

Introduction to Jinling Metals 2023

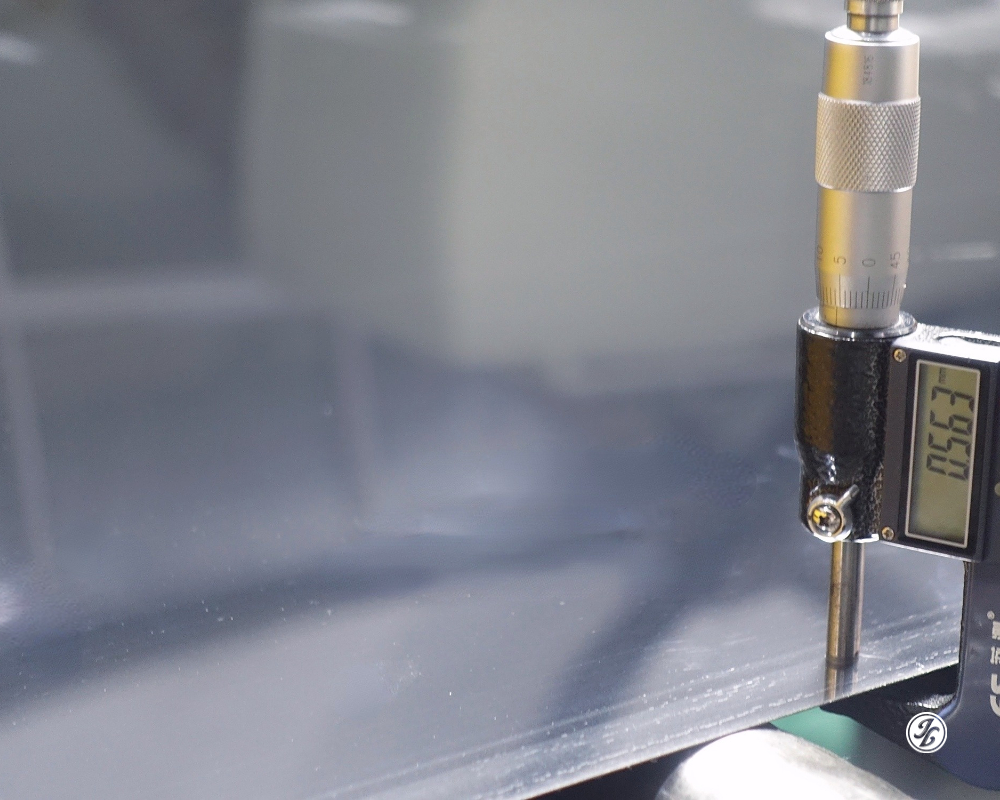

Regular specifications for the cold-rolled stainless steel coils:

| Width | 1 meter | 4 feet | 5 feet |

| Thickness | 0.3mm~3.0mm | 0.3mm~5.0mm | 0.3mm~3.0mm |

Surface Treatment

| Finish Code | Processing Method and Application | |||||||

| 2D | This finish is not reflective and is made through cold rolling, heat treatment and pickling. Its typical uses include petrochemical plants, auto parts, construction materials and pipes. | |||||||

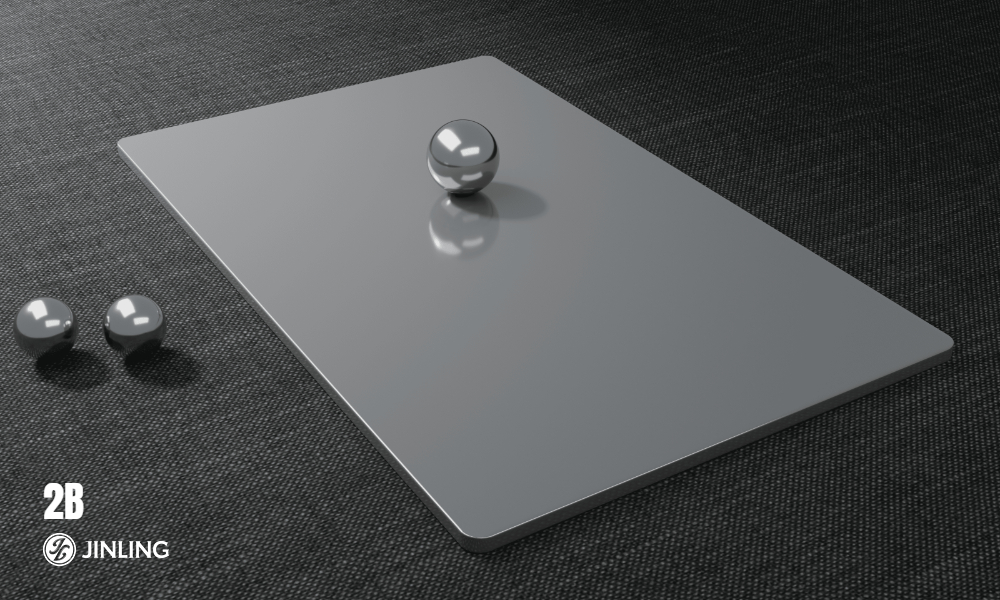

| 2B | This finish is made by applying a light cold rolling pass to No.2D. It is more reflective and less rough and provides better mechanical properties than No.2D. It is commonly used for almost all applications. | |||||||

| No.4 | This finish is made through polishing with 150-180 grit abrasives. High grit numbers create finer polishing lines and more reflective finishes than No.3. This finish is widely used for bathtubs, architectural materials and food processing. | |||||||

| HL | Featuring a series of patterns, this finish is made through polishing with moderate grit abrasives. Its common uses include sashes, doors or other panels of buildings. | |||||||

| BA | This finish is made through cold rolling, bright annealing, heat treatment and then a light cold rolling pass. It is widely used for applications where a highly reflective surface is desired, including home appliances, small mirrors, kitchen appliances and architectural materials. | |||||||

| No.8 | No.8 finish also known as #8, 8K or mirror finish. This finish requires a base material of 2B or BA finish to process. Accoding to different machines and demands, #8 can be polished in coil or sheet to attain a mirror-like effect. Brightness is over 1300 GU(20 degrees); Roughness is smaller than 0.02um. It is widely used in logo, architectural decorations, exquisite fabrication. | |||||||

Working Daily

Sheet Processing

QC & Delivery