Stainless steel lives with us.

Maybe you are now wearing a stainless steel bracelet or watch, walking on a stainless steel made staircase, in a stainless steel frame building, and every day, you have to drive through a bridge constructed by stainless steel back home, walk through a stainless steel fence, open a door of stainless steel, turn on a stainless steel faucet to wash your hands, and prepare for the dinner in the stainless steel kitchen. Well, it is not the end. You may want to have you own ‘hygge’ time, so you lean on the stainless steel Juliet balcony, enjoying the moonlight and gentle breeze.

From public construction to a small piece of accessory, can you imagine a modern world without stainless steel? But to build this world, stainless steel only takes a century. Unlike iron, which has been in use for over a thousand years, stainless steel is definitely a newcomer to the materials science world. Not until 100 years ago, did the stainless steel is produced. Nowadays, it has been in every facet of human life.

Iron from the universe

The earliest discovery of iron is on the meteorite. Before the method of melting iron ore was invented, humans could not attain the raw iron, so the iron has been considered as a precious metal with mystery.

The discovery and mass use of iron is a milestone in human development. Iron brought human beings from the Stone Age and Bronze Age to the Iron Age and promoted the development of human civilization. It is the foundation of the modern chemical industry and essential metal material for human progress.

Ancient oriental use of chromium

Among all metals, chromium is the hardest one. In metallurgy, chromite is used to produce ferrochrome and metallic chromium. Ferrochrome is an additive to produce steel which can be endowed with high strength, wear resistance, corrosion resistance, heat resistance, and oxidation resistance.

Chromium has been utilized earlier than we thought. Dated back to 3000BC, in ancient China, Qin Dynasty was ruled by China’s first emperor who died and buried in his own royal mausoleum which is known as Terracotta Army. In 1973, archaeologists unearthed 3 swords from Terracotta Army. The swords were buried 6-meter beneath wet soil for over two thousand years without any rust and stain, and they can cut through dozens of papers. Specialists analyzed and found out that on the swords’ surface, there are filmed with chromate oxidation to protect the metal from corrosion, which is not used in other countries until the 1930s.

Invention of stainless steel

Over a century, scientists and metallurgists have developed and invented methods to make stainless steel, to change the properties and enter mass production. The 18th century makes a great process in the invention of stainless steel, which is a time of chemical elements discovery. Nickel, molybdenum, and chromium, these essential elements of corrosion resistance were discovered during the 18th century. From the 19th century to early 20th century, scientists and metallurgists tried to deepen understandings of metal properties, coming with researches and studies toward alloys, providing theoretical support for stainless steel invention. Stainless steel has entered rapid development. With the World War starting, increasing military needs boosted the improvement of weapons which requires excellent properties of corrosion resistance.

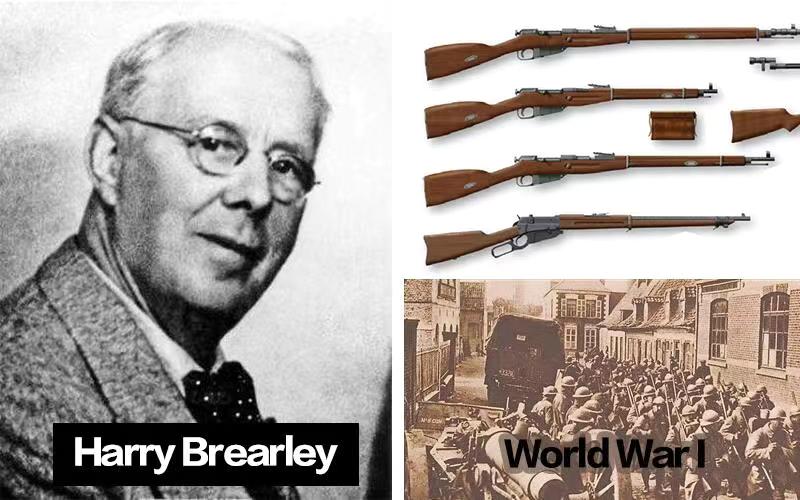

At this joint, it is time to mention Harry Brearley.

At the dawn of WWI, in 1912, Brearley was given a task by an arms manufacturer who wishes to prolong the lifespan of the gun barrels which were eroding away too quickly. That is how Brearley started to study erosion resistance, not corrosion resistance and he began experimenting with steel alloys containing chromium with a different measure of carbon.

On the 13th August 1913, Brearley created a steel with 12.8% chromium and 0.24% carbon, identified to be the first stainless steel. Mist is covered over the discovery of stainless steel. The story has it that the invention of stainless steel is an occasional event. When Brearley got frustrated in studying the metal, the threw away several experimental samples into rubbish at the corner. Only found one shinning without being rusted.

However, another version sounds less interesting. Brearley found his new alloys under the microscope that resisted the chemical attack. He proceeded his experiment and used lemon juice and vinegar to test the alloy which was gladly found out that they were potential for the cutlery industry. He cooperated with his friend Ernest Stuart to produce knives, for which Brearly had initially decided to name ‘rustless steel’, dubbed it ‘stainless steel’ and this name stuck.

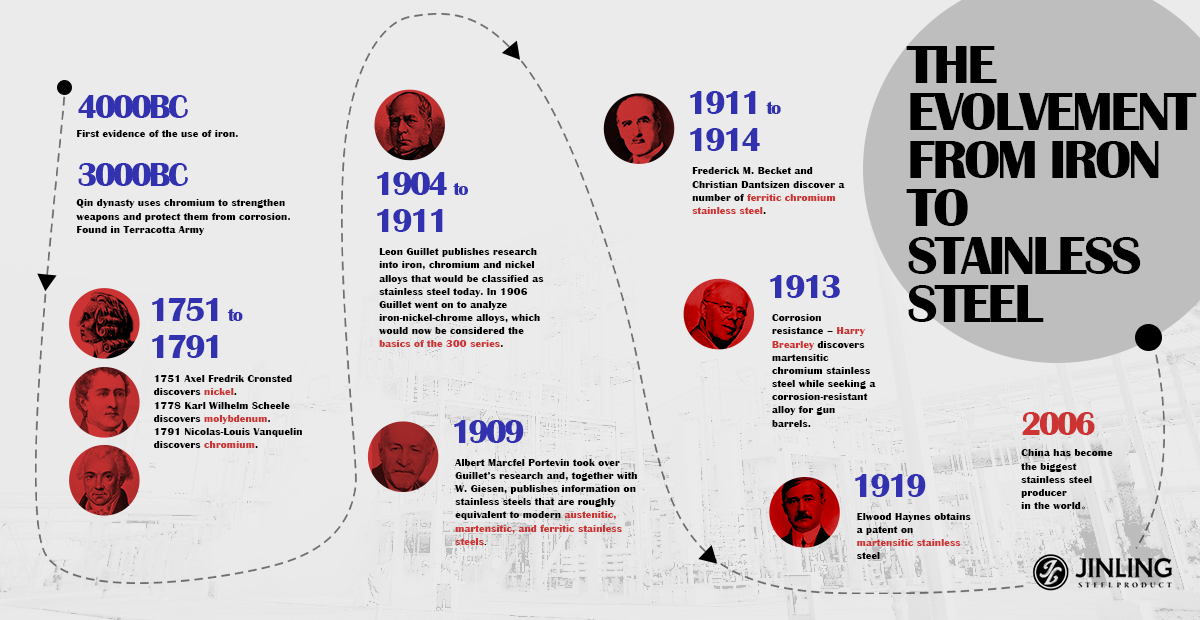

Milestones:

4000BC First evidence of the use of iron

3000BC Qin dynasty uses chromium to strengthen weapons and protect them from corrosion. Found in Terracotta Army

1751 Axel Fredrik Cronstedt discovers nickel

1778 Karl Wilhelm Scheele discovers molybdenum

1791 Nicolas-Louis Vanquelin discovers chromium

1875 a Frenchman named Brustlein detailed the importance of low carbon content in successfully making stainless steel

1904-1911 Guillet publishes research into iron, chromium and nickel alloys that would be classified as stainless steel today. In 1906 Guillet went on to analyze iron-nickel-chrome alloys, which would now be considered the basics of the 300 series

1907 First commercial electric arc furnace(EAF) established in the US, which is still the main process to produce stainless steel

1909 Albert Marcel Portevin took over Guillet’s research and, together with W. Giesen, publishes information on stainless steels that are roughly equivalent to modern austenitic, martensitic, and ferritic stainless steels

1911-1914 Frederick M. Becket and Christian Dantsizen discover a number of ferritic chromium stainless steel

1912 While working for Krupp, Eduard Maurer and Benno Strauss are granted patents on two chromium-nickel stainless steel

1913 Corrosion resistance – Harry Brearley discovers martensitic chromium stainless steel while seeking a corrosion-resistant alloy for gun barrels.

1919 Elwood Haynes obtains a patent on martensitic stainless steel

.

.

.

2006 China has become the biggest stainless steel producer in the world

----------------------------------------------------------------------------The Evolvement from Iron to Stainless Steel--------------------------------------------------------------------------