When you’re choosing guardrails for a project, there are many reasons why you may opt for stainless steel over other materials. For example, you may prioritize appearance, durability, corrosion resistance, or cost, with the decision likely to be influenced by factors such as the location of the guardrails, the environmental conditions, and the budget.

With the carbon emissions targets set, it is widely recognized that the world needs to urgently reduce carbon emissions in order to avoid the worst impacts of climate change. More and more builders and designers are considering sustainability and carbon footprint issues when selecting building materials to reduce the negative environmental impact of raw materials.

Therefore, if you are considering investing in guardrails, choosing a stainless steel guardrail could be wise for both you and the environment.

Sustainable Stainless Steel

In today's business era, being environmentally conscious is a key consideration for most people. Going green and ensuring sustainability has become increasingly necessary.

● Green Raw Material - Stainless Steel

According to the World Steel Association, steel is the world’s most recyclable material. It plays a critical role in sustainable design and alternative energy development.

The recyclability and high scrap value of stainless steel reduce the need for virgin raw materials. The result is significant savings on energy costs and emissions in the manufacturing of new products.

● 60% of All New Stainless Steel Comes from Recycled Materials

Stainless steel typically contains a significant amount of recycled content during the production process. Even if stainless steel is used for a considerable period of time, its value remains.

The stainless steel-producing members of the Specialty Steel Industry of North America have indicated that the average recycled content of the 300 series stainless steel grades that are used in the architecture, building, and construction market is approximately 75 to 85%.

Stainless steel is highly recyclable without loss of quality, with 60% of all new stainless steel coming from recycled materials. Regardless of the precise composition of the metal, stainless steel can be easily recycled for different uses, making it a more sustainable option.

● High Scrap Value of Stainless Steel

By using recycling stainless steel, the process consumes less energy and produces fewer emissions, which plays an important role in reducing greenhouse gas emissions, saving energy, and protecting natural resources.

What makes stainless steel valuable is the other metals used in its creation. A piece of stainless steel may contain chromium, nickel, copper, and a variety of other expensive metallic elements, which can be separated and reused when the scrap stainless steel is melted down. At the end of life, stainless steel is recaptured and recycled into new metal at amazingly high rates.

In the industrial equipment and the building and infrastructure segments, 92% of stainless steel is captured at the EOL for use in new stainless or carbon steel. The EOL recapture rates for other common applications are as follows:

- transportation, 87%;

- household appliances and electronics, 70%;

- other metal goods, 60%.

Manufacturers use stainless steel from a variety of sources, including industrial waste and discarded products, as raw materials for new production. Recycling scrap stainless steel reduces the need for new metal extraction and reduces the environmental impact when metal is extracted.

● Recyclability of Different Materials

Stainless Steel: Stainless steel is considered one of the most recyclable materials. Recycled steel only accounts for about 40% of the total amount of steel produced, even though more steel is created than is destroyed, resulting in a 60% recycling rate.

Wood: It can be denied that most wood waste can be reused as a building material. However, it’s not as simple as chucking every piece of wood you find into your curbside recycling box. The reason for this is that recycling wood isn’t a straightforward process. The wood’s recyclability depends on the type of wood and whether it is contaminated with any other substances.

Glass: Glass is sometimes difficult to recycle due to its weight compared to other materials, which impacts transport. Glass recycling needs to meet certain requirements, that is the glass must be clean and the particles must be large enough to separate by color using optical equipment.

Stainless steel is the ideal choice as the guardrail material if you really care about longevity and the environment.

Environmental Benefits of Stainless Steel Guardrails

Stainless steel is a highly sustainable material with numerous environmental advantages, especially when used in applications such as guardrails.

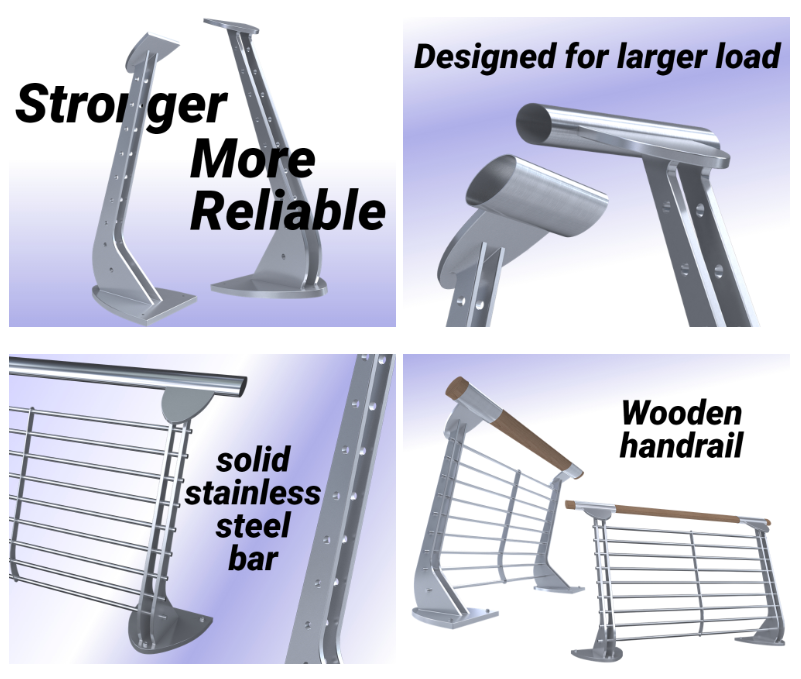

● Stainless Steel Guardrails Offer Greater Strength And Durability

Stainless steel is known for its exceptional durability and resistance to corrosion, which allows guardrails made from this material to have a long lifespan.

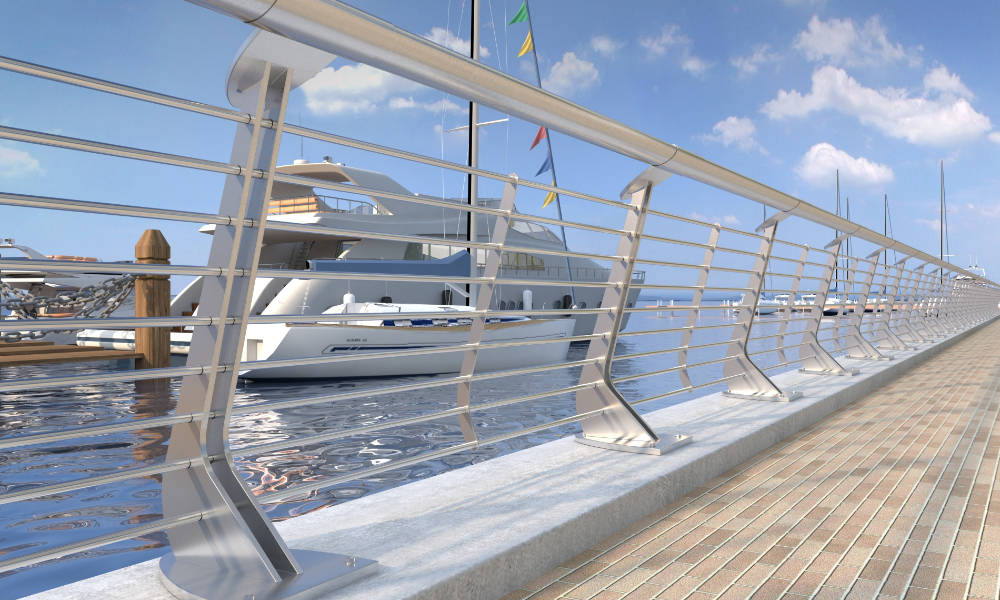

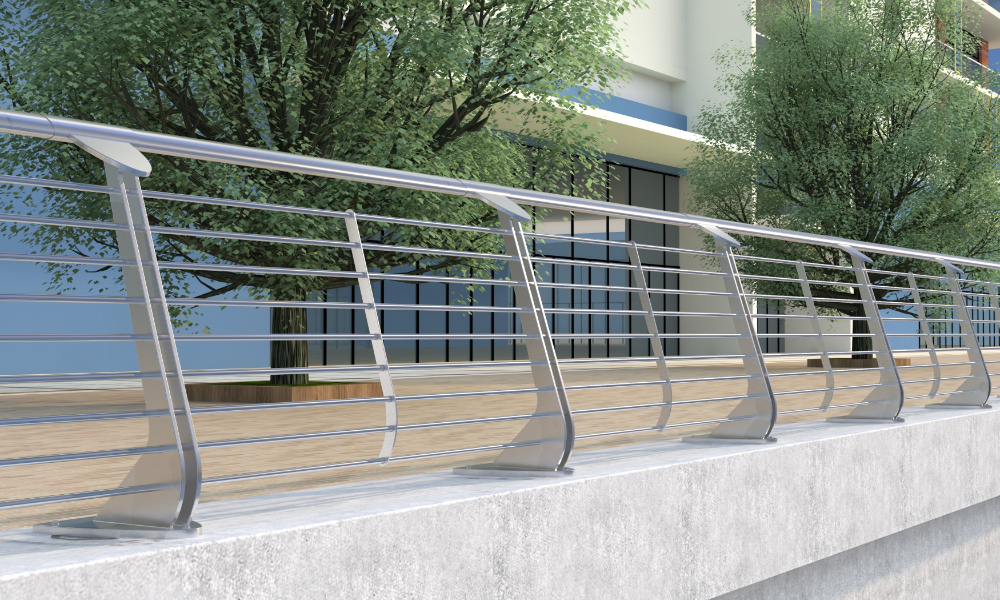

Stainless steel guardrails are suitable for various environmental conditions, including indoor and outdoor applications such as coastal areas with high salt exposure, or regions with extreme temperatures. Their ability to withstand harsh conditions means that they last longer and have less impact on the environment.

The durability means a less frequent replacement, which reduces the overall demand for resources and energy associated with manufacturing and transportation.

● Stainless Steel Production Is Cleaner Than Ever

Increased government environmental protection requirements and people's growing awareness of environmental protection have led companies to produce stainless steel in a cleaner way than ever before.

Beijing is strict in the regulation of pollution during production. The anti-pollution investigation in the industry is a strong force to regulate business owners to upgrade the system from production to operating philosophy. In stainless steel mills and manufacturers, almost all scraps are ended up in the recycle station. It is far from enough to do just average. To maximize every dime of the material, so as to enlarge the product cycle, our duty is to produce excellent stainless steel products for every user.

Jinling Steel Is Committed to Providing You with Sustainable Stainless Steel Guardrails and Solutions

In a word, sustainability is vital to us. Choosing stainless steel for guardrails can contribute to more sustainable and environmentally responsible infrastructure.

By understanding the sustainability of stainless steel, you can believe and start investing in more applications made from this material.

Jinling Steel is continually working to improve the sustainability of our manufacturing processes. We are pleased to provide you with quality guardrail systems and to build a green and sustainable future with you. Contact the Jinling Steel team today to find your project's perfect and sustainable guardrail or railing solutions.