China launched the Shenzhou XII spacecraft, its seventh manned spaceflight, on 17th June morning, sending three astronauts to the core module of its permanent space station. The spacecraft, atop a Long March-2F carrier rocket, blasted off at 9:22 am at the Jiuquan Satellite Launch Center in northwestern China. They will be stationed in the core module for about three months, completing their missions. In October, 2021, China plans to send another 3 astronauts to the core module, further developing the construction of the Tiangong station, Chinese Space Station.

This is a thrilling improvement for human, making it more achievable for human to step in and even live in the space. SpaceX is making the attempt.

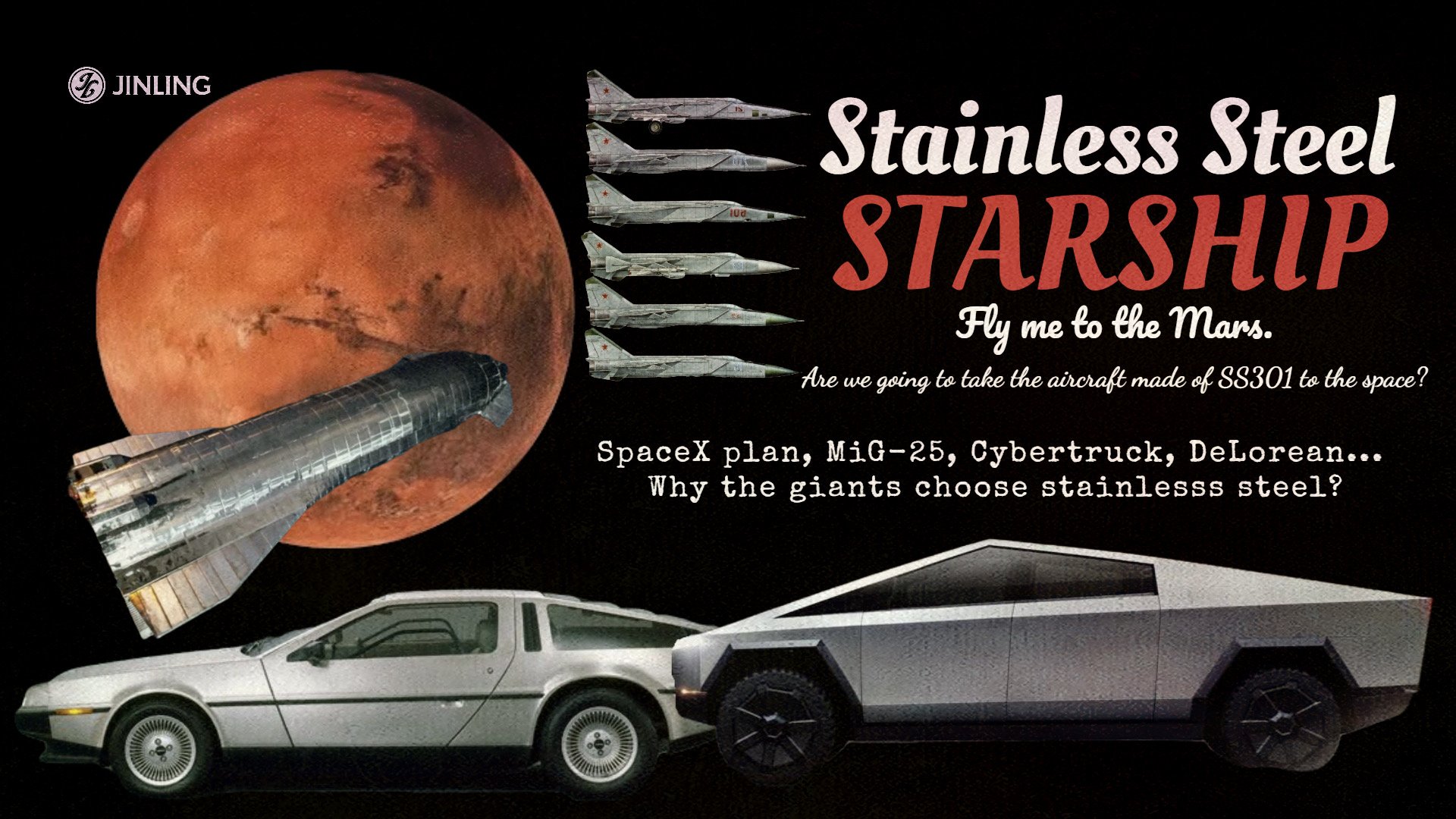

On 15th June, Elon Musk tweeted a photo of SpaceX. The video shows a grand view from the high bay of the base, seeing the whole starship booster.

The starships look like two enormous large stainless steel cans from far. The starship prototypes, as Musk introduced, are built by stainless steel 301.

In 2019 a reporter asked him where the stainless-steel comes from, Musk responded:

"It’s just 301 stainless. Let me put it this way: 304 stainless is what they make pots out of. There’s plenty of it." In 2020, he furthered explained that “some parts will use 304L, as it has toughness at cryo temps. Will move to internally developed alloys probably end of year.”

Do you believe that the stainless steel cups and pots you used maybe have a higher grade of quality than the rockets use? When Musk unveiled a Starship prototype in 2019, he explained that the reason they chose to design a stainless-steel flight vehicle is because "it’s obviously cheap, it’s obviously fast -but it’s not obviously the lightest. But it is actually the lightest. If you look at the properties of a high-quality stainless steel, the thing that isn’t obvious is that at cryogenic (cryo) temperatures the strength is boosted by 50 percent."

This makes Starship production a bit more cost effective compared to the production of other rockets that are made of carbon fiber. "The carbon fiber is $135 a kilogram, 35 percent scrap, so you’re starting to approach almost $200 a kilogram. The steel is $3 a kilogram," he said. So, stainless-steel is the most affordable option that offers high strength and heat-shield properties. Musk expects to reduce manufacturing costs to $5 million per stainless-steel Starship vehicle as they scale-up production.

Seems Elon Musk has an affection on stainless steel. Cybertruck of Tesla, “is designed for superior strength and endurance, from Ultra-Hard 30X Cold-Rolled stainless-steel structural skin to Tesla armor glass”. 30X Cold-Rolled stainless steel is a new stainless alloy which was developed by Tesla for their starship rocket, which is supposed to be superior to stainless 304. For some reasons, the SpaceX changed the materials to stainless 301. Maybe it is just because making a truck is more familiar for the Tesla team.

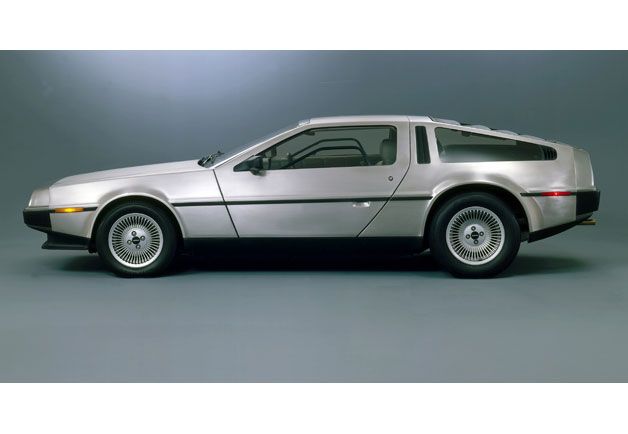

The stainless steel affection is not rare in the motor vehicle industry. In the early 1980s, DeLorean made a stainless steel vehicle which used 304 stainless steel for its body, a relatively common grade of steel.

Some might doubt that if the stainless steel is too heavy for a flying object. In the military area, stainless steel has successfully proved the possibility of stainless steel in MiG-25 produced by the Soviet Union as early as the 1960s.

The MiG-25 is made of stainless steel. Almost completely.

This is due to two reasons:

1.Titanium is expensive, even in the Soviet Union which was a primary producer of titanium at the time.

Also, thin titanium is hard to weld.

2.The thermal stress of flying at Mach 2+ is intense (The plane's skin heats up a lot.)

“Using titanium rather than steel would have been ideal, but it was expensive and difficult to work with. The problem of cracks in welded titanium structures with thin walls could not be solved, so the heavier nickel steel was used instead. It cost far less than titanium and allowed for welding, along with heat-resistant seals.[13] The MiG-25 was constructed from 80% nickel-steel alloy, 11% aluminium, and 9% titanium.”

Maybe it is MiG-15 that gives a hint to Musk’s commercial idea of a starship. "Build it as big as you can, and the other details become easier." or maybe "Big, simple, and cheap means less design problems and a quicker path to market."

stainless steel starshipstainless steel starshipstainless steel starshipstainless steel starship