I assume that disposable materials have the right to be one of the greatest inventions in human history, or either, disasters. People can use plastic products, wooden products conveniently without thinking of non-biodegradable issues and limited natural resources. Till today, even though the idea that the disposable legacy is harmful has become a sharing concern for many people, just as the negative legacy to nature, the convenience is also toxic that people can't get rid of. After decades of convenience-enjoying, the revenge has begun when the human has been paying back by sacrificing other features and it is coming for us.

Recyclable: Does it really count?

Do you still believe that the plastic on your hand is thrown into the “recycled” ashbin, and then it will end up in the next reuse? As long as it has the triangle arrow symbol on it, it should be A-OK to go in the blue bin — right? Not necessarily. Waste management companies often refer to this behavior as wishful thinking or eagerly hopeful recycling. The recycle mark largely is a self-comfort for users and a “reasonable” excuse for giants companies to keep producing. Plastic is not the only case, “Despite significant efforts in a number of countries and regions, many metal recycling rates are discouragingly low, and a ‘recycling society’ appears no more than a distant hope,” states Recycling Rates of Metals: A Status Report. The recycling situation is critical.

Are laziness and the mind that we take things for granted making the situation worse? The responsibility to break the dilemma falls not only on the individual, but also on the brands, industries, and the chains and webs people make. It is time to take action rather than sitting along and worrying about the disaster.

Metal pollution: Under the pandemic, it is facing a new challenge.

In the metal industry, more and more brands and institutes start to face the complex relationship between the industry and the deteriorating environment. It is not a new tone that we need a sustainability thinking mode to reform the industry, but in the developed traditional industry, typically heavy industry, like the metal industry, the consciousness has not become a common view and hardly been practiced by users, brands, and industry.

Under such a weak awareness, currently, an enemy of us also threatens the recycling process. “During the early days of the pandemic, the impact of solid waste disposal and recycling on the environment was not foremost in people’s minds. While it seemed prudent at the time, many towns ceased their recycling programs and curtailed operations at transfer stations and other solid waste facilities.” states We still need to reduce, reuse and recycle during a pandemic.

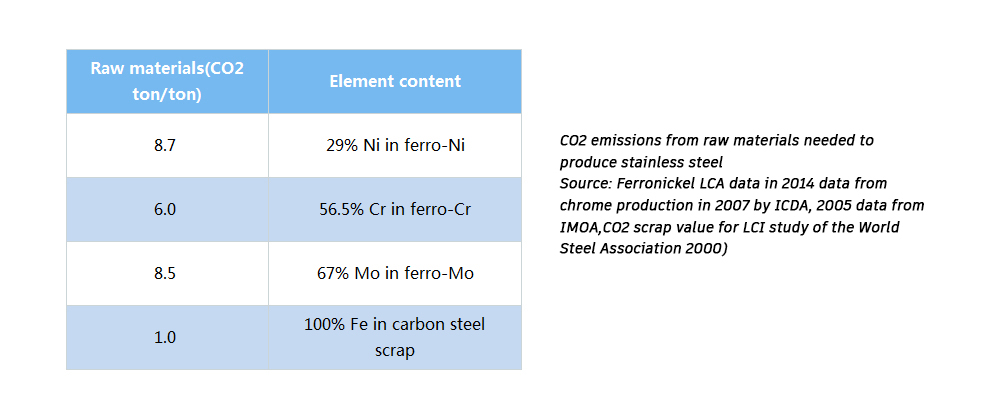

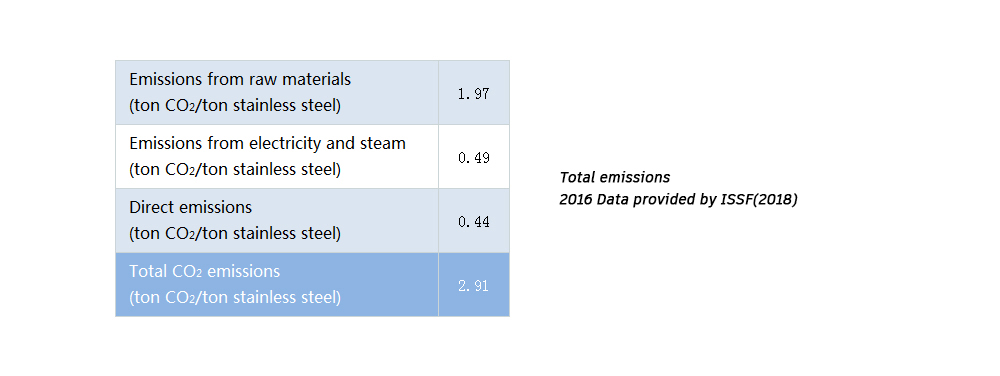

If say the pandemic is a random case, another problem seems to be more critical and common. The pollution lies in the stainless steel industry itself. For example, the waste acid in the iron and steel industry mainly comes from the surface pickling production process of sulfuric acid. Every one ton of stainless steel production produces about 0.5 tons of waste sulfuric acid. Waste acid is far more harmful to groundwater than chemical wastewater. When it seeps into the ground, it also dissolves heavy metal compounds in rocks and soil into rivers or underground through reactions, causing serious pollution to rivers and groundwater. Using this polluted water irrigation has caused serious pollution to the soil. Acid emission is only one of the problems, fuel waste air also counts. These need the recycling technology to develop and the producers to practice the emission standard strictly.

High recycling rate: Stainless steel is a 100% recyclable material.

There is enough for being a pessimist. The good is that, the scrap metal recycling market is driven by the increasing price of raw materials. In addition, rising concerns about the impact of mining on the environment are anticipated to boost the growth of the scrap metal recycling market. Stainless steel undoubtedly owns the superior condition to be recycled. As a high-quality sustainable material, stainless steel has a high value and a complete industrial chain, providing a good foundation and support for this development.

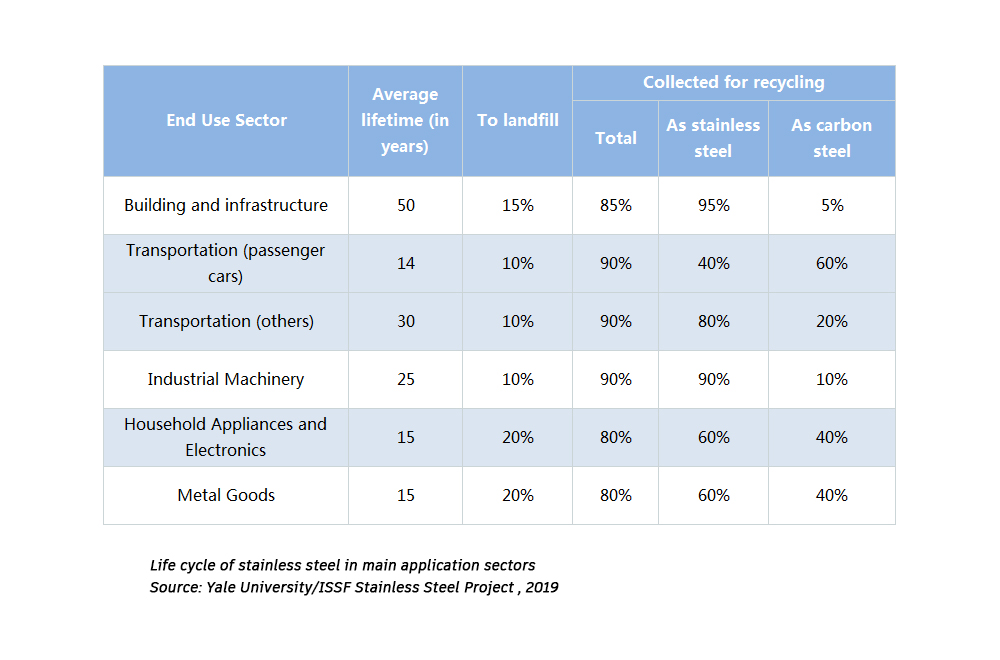

“Conducted by Barbara Reck, Senior Research Scientist at Yale University, the study ‘Comprehensive Multilevel Cycle of Stainless Steel in 2015’ concluded that on average, 85% of stainless steels are recycled once they reach their end of life, either to become new stainless steels (56%) or a valuable iron source for carbon steels (29%)”, stated in Recycling Magazine.

Stainless steel: What solutions can it bring to us?

Ultimately, the most environmentally friendly materials are corrosion resistant and durable, have high-recycled content and recapture rates, provide long service life, and reduce resource use. Stainless steel provides all of these benefits.

1. Long EOL (end of life) and High EOL-RR (end-of-life recycling rate)

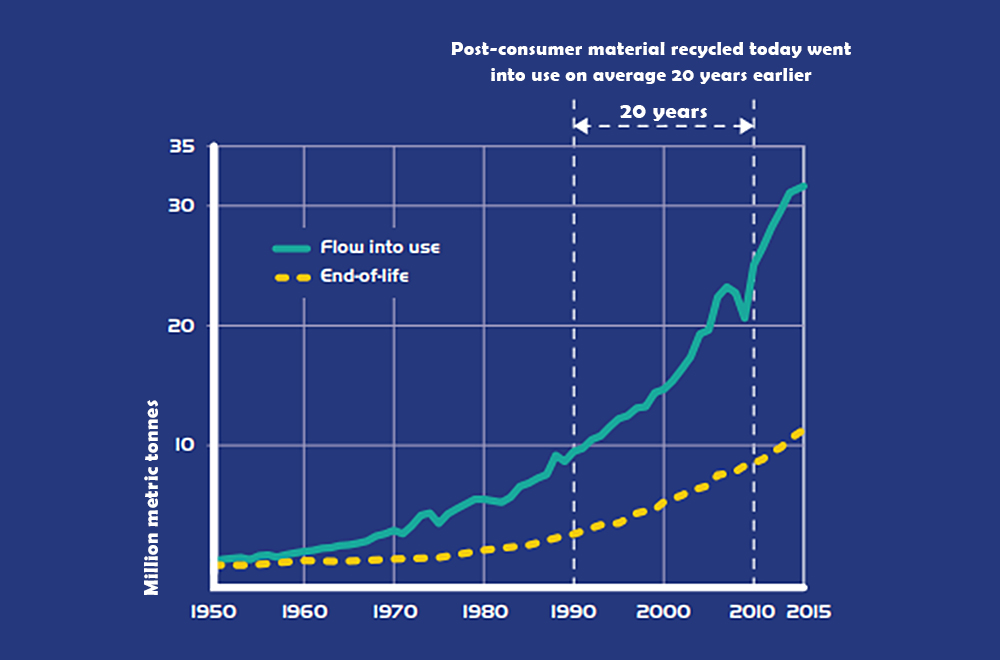

Stainless steel is 100% recyclable and has no quality reduction during the recycling process. The durability and longevity entitle pretty long EOL(end of life), and long before they are available for recycling. The average life span of stainless steel is twenty years, but in auto-area, because the life of the vehicle is limited, the stainless steel used in cars is comparatively lower. There still are many living witnesses, typically in buildings, stainless steel is still in use for decades and even beyond a century. With long EOL, the EOL-RR(end-of-life recycling rate) of stainless steel is also encouragingly high. Recycling is highly beneficial both in the economy and the environment. The high value of stainless steel scarp makes it worth collecting and reusing, which is a directly driven force for recycling and makes the recycling rate high. Scarp as a raw material supports stainless steel production. 60% of all new stainless steel comes from recycled material. In principle, and as long as product design and recycling technologies allow, stainless steels can be recycled infinitely. Durability and recyclability are two of the key contributions which stainless steel makes to sustainability.

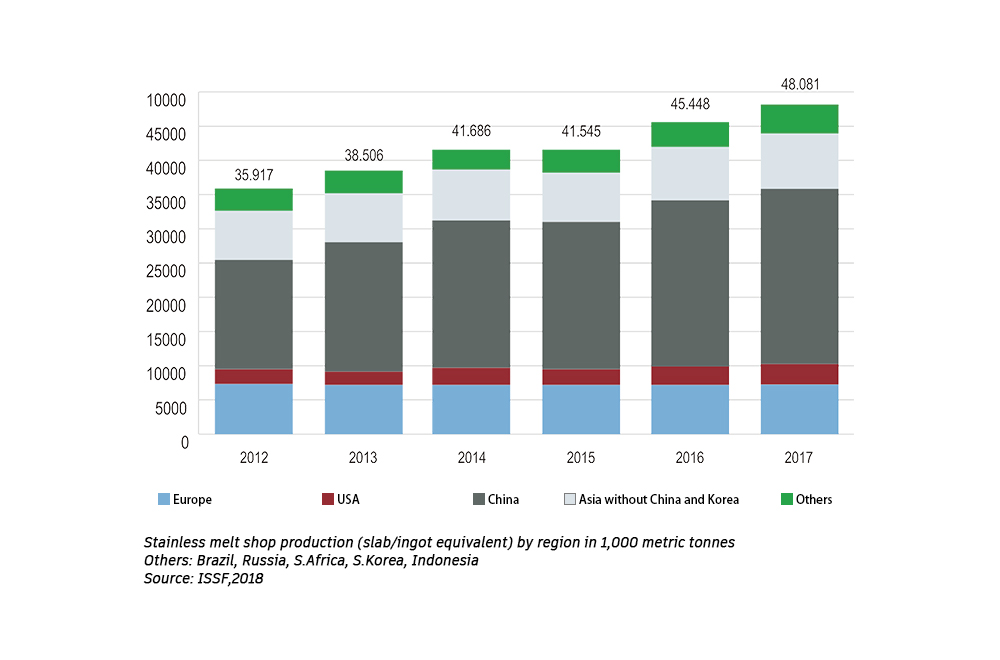

In recent years, the EOL-RR will keep increase because of the participation of China, the largest producer and consumer of stainless steel. The growth of China’s stainless steel industry is only in the recent 20 years, which means that when the averaged EOL of stainless steel products, 20 years, comes to an end, the recycling rate in China will increase in seeable days. It is predicted that in 2020, the stainless steel recycling golden age will appear soon.

Source from Team Stainless

2. Energy and resource reserved

What stainless steel contributes to the environment protection is not only the reusing rate and recyclability, but also its excellent performance in energy and resources devices, such as the generation of solar, biomass to energy, nuclear, geothermal, and wave power. (link to 304, 304L, 316L Stainless Steel for Nuclear Power, which is the Champion? )

Stainless steel is widely used in our life because of its safety. Stainless steel is used to store and transport potable water to minimize the loss to the environment and to clean wastewater. Its usage covers large public water facilities and spreads to small filtration units which clean greywater to reduce potable water consumption. It is an ideal material that “combines with low run-off stainless steel roofs and drainage systems to maximize the capture and use of non-potable water sources and to minimize the structure’s overall environmental impact.”

Stainless steel is also an effective material to reduce heat in buildings for the high Solar Reflectance Index (SRI) of the stainless steel surface. The solar reflectance index (SRI) is a measure of the constructed surface's ability to reflect solar heat, as shown by a small temperature rise. Stainless steel surfaces can reflect away and dissipate heat, thereby reducing building cooling energy consumption and alleviating the urban heat island effect.

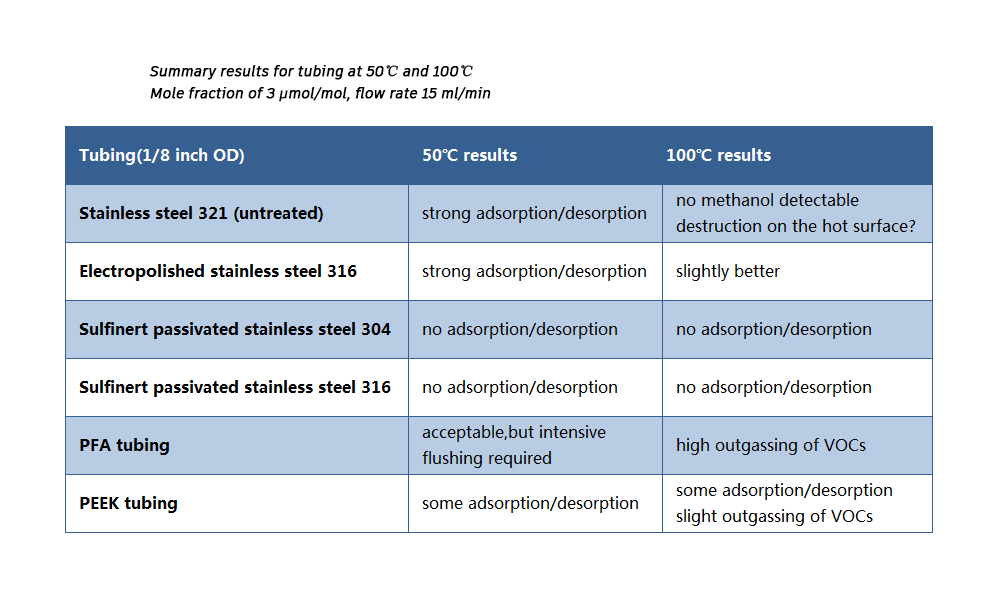

3. No VOC (volatile organic compounds)

VOCs (volatile organic compounds) are an important standard linked to health issues, air pollution, and greenhouse gasses. VOC problem commonly happens in the interior environment. The VOC in the room mainly comes from decoration materials such as latex paint, wallpaper, ground, insulation materials, adhesives, etc. Selecting decorative materials is key to health because these are with you for a long time. Stainless steel is an ideal material in interior decoration because it produces no VOC emissions which ensure indoor air quality clean and healthy. Stainless steel has been popular in design because it is flexible and modern. Wall covers, wall claddings, furniture, kitchen stuff made by stainless steel are commonly seen these days. Another undefeatable merit of stainless steel is the corrosion resistance and it is easy to clean.

Conclusion: Sustainability is a lifestyle we advocate.

Stainless steel has a wide usage range. From a screw to a rocket, stainless steel is all around. Theoretically, stainless steel is 100% recyclable. However, in reality, there are restrictions on the total amount of economical coverage. One can amalgamate steel products with other materials. For example, in combination with concrete. This cannot be easily – and, crucially, economically – separated and effectively render the raw material only fit for disposal.

Therefore, the most economical way to be sustainable is to extend the lifespan of stainless steel. It needs users’ effort as well as the awareness among society and industry. Let’s change in something subtle. At least, reduce the use of disposal tools and reduce the change of metal products. There is a quote by a recycling industry practitioners, Lou Zhongpin says,” Plastic itself is not sinful, what is sinful is human habits” and “What we should pursue is a more environmentally friendly lifestyle”.

-----------------------------------------------------------------Our duty and responsibility|| Sustainability. Let it last longer -------------------------------------------------------------------------