"How can a thin blade sustain the high intensive jumps, and the friction caused by the high speed?” Have you ever thought of this question when watching Beijing Winter Olympics? In this article, let's explore another steel world that is not so familiar for most people.

History

Ice skating, in one form or another, has existed for thousands of years. Evidence suggests that as long ago as 1000 B.C. Scandinavians were fashioning crude blades from the shank or rib bones of elk, oxen, and reindeer and strapping them onto boots.

The Dutch added edges to ice skates in the 13th or 14th century. These ice skates were made of steel, with sharpened edges on the bottom to aid movement.

A Scene on the Ice by Hendrick Avercamp in first half of 17th century

What about in China?

Ice skating was also practiced in China during the Song dynasty and became popular among the ruling family of the Qing dynasty. Ice skating was called “冰嬉”(Bingxi, meaning playing on the ice) in Qing Dynasty. It was a traditional activity and a “compulsory course” to the royal family because it was regarded as a military skill.

During Qianlong’s reign (1735–1796), this activity reached a peak during ancient China. More than 200 national ice sporting events were held during Qianlong’s reign. One of the sports was so similar to today’s short track speed skating, which is described as in an ancient book, “… they wear shoes with an iron blade, sliding on the ice like a shooting star. Who take the flag first on the finish is the winner of the game. This activity is called ice skating…”. However, the ice sport faded quickly after Jiangqing’s reign (1796-1820).

Types of skates

There are three basic types of ice skates: hockey skates, figure skates, and speed skates.

Speed skates are designed for optimum swiftness in one direction, with the skater moving right foot over left. The speed skate features a straight blade up to 18 inches (46 cm) long and 0.03-0.06 inch (0.08-0.15 cm) wide. The blade is reinforced with hollow steel tubing. The boot is constructed of very light, thin leather.

Hockey skates are constructed to allow the skater to move both right foot over left and left foot over right. The blade, usually 0.06 inch (0.15 cm) wide, is also reinforced with hollow tubing. The boot is short, measuring 4-5 inches (10-13 cm) from the sole, and reinforced with plastic caps and extra layers of leather at the toe. This protects the skaters' feet from the blades of other skates. The original hockey skate was made of leather with a plasticized sole, a safety tip at the rear, and a hard toe. A ballistic-proof nylon was then introduced that provided even greater protection against cutting. The newest innovation features a plastic molded boot with plastic stanchions and plastic tubing. A heavily padded, removable liner helps to control the fit.

Figure skates are fitted with a 0.125-inch (0.32 cm) steel blade designed for spinning. The blade is hollow on the bottom so that only the outer edges touch the ice. A series of sharp angles at the front of the blade called toe picks facilitate landing from toe jumps. The figure skate has a high boot, measuring 7-8 inches (18-20 cm) from the sole to the top, completely covering the ankle.

Materials of the blade:

Blades are generally made of tempered steel and coated with high-quality chrome. Some blade manufacturers may add titanium to the metal. The ice-skate manufacturer contracts with outside manufacturers to supply them with blades in various styles and sizes. Competitive skaters (as opposed to recreational ones) usually have their blades mounted by a specialist.

The carbon-steel blade is generally used by beginners. The carbon content decides the quality of the blade. The hardness of the skates should be the same in the same games, for the reason that the higher level of steel, the longer using time of the blade. Under normal circumstances, carbon The surface hardness of the ice blade made of steel after heat treatment is HRC56~64.

The surface of the blade needs to be plated with a layer of chrome to prevent corrosion.

For example, the chrome-plated layer of the working surface needs to be polished off before use. But these skates are prone to passivation, and the solder (usually silver brazed) that attaches the blade to the sole of the boot may not be able to withstand the stress of repeated jumping and desoldering.

Stainless steel, high-grade carbon steel blades are of higher level for their strong corrosion resistance and hardness, which allow skaters to complete difficult movements.

These blades are usually coated with a layer of titanium compound. After grinding, the maximum hardness on both sides reaches HRC85, which reduces the friction between the skate and the ice and improves the sliding speed, such as 12C27 and 14C28N from Sandvik, Sweden. 14C28N is martensitic stainless steel, which has excellent edge properties, very high hardness, and corrosion resistance after cold working.

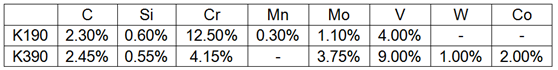

As for professional athletes, most of them adopt the power-metallurgy blade for their skate, such as the K190 and K390 produced by Bohler, an Australian company.

No one wants to change their skates during competitions. Therefore, professional skates require the blades to adapt with the ice of different hardness and to sustain frequent jumps and skills.

By coating titanium nitride or titanium carbide on both sides of the blade, after grinding and sharpening, the hardness can be improved to HRC80-85 and the roughness is lower to Ra0.1~0.2. Thus, this material and process improve the life of the blade without reducing the toughness of the blade, reducing the friction between the blade and the ice so as to increase the speed.