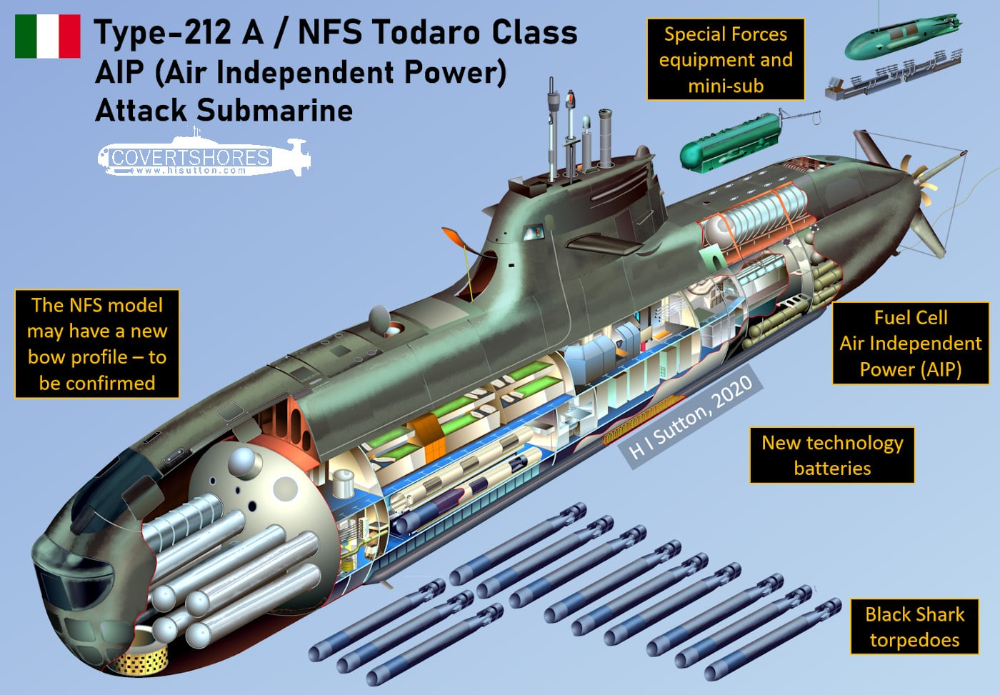

The Italian Type 212 NFS stainless steel submarine is set to be constructed with assistance from the German TKMS Group, which will contribute various subsystems, including fuel cells. The 212 NFS submarine represents an upgraded and enhanced version of the 212A submarine. Available information suggests that the length of the 212 NFS hull will increase by 1.2 meters, resulting in a total length of 58.3 meters. The pressure hull itself will be 41 meters long, while the hull width will remain unchanged at 7 meters. The surface displacement will be around 1600 tons, with an underwater displacement of approximately 2000 tons. The hull extension will enhance fuel carrying capacity and living space for the crew, which will consist of 29 individuals.

Constructed from non-magnetic amanox high-strength stainless steel, the hull will feature a fouling release coating material containing fluoropolymer on its surface. This coating helps to minimize dirt accumulation, reduce resistance during sailing, and lower fuel consumption. Additionally, a new High-Pressure Blowout System (HEBD) for emergencies will be implemented.

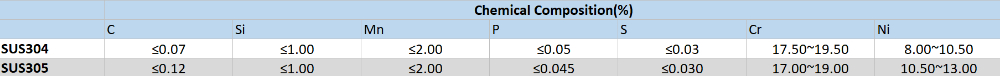

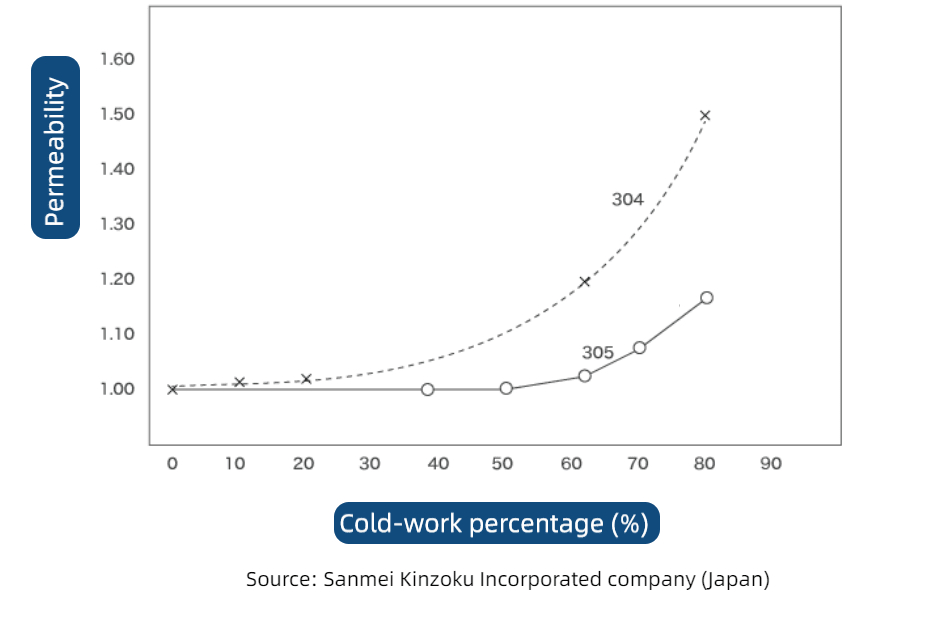

Stainless steel 305 (SUS305) is commonly known as a type of non-magnetic stainless steel. Unlike the standard austenitic stainless steel SUS304 (18Cr8Ni), which becomes magnetic when subjected to cold working due to a martensitic transformation, SUS305, also belonging to the austenitic stainless steel family, contains a high amount of nickel (Ni). This high nickel content contributes to the formation of a stable austenite phase, enabling SUS305 to maintain its non-magnetic state even after undergoing cold rolling. The increased nickel content in SUS305 materials allows them to retain their non-magnetic properties throughout the processing stages.

In addition, the presence of chromium in stainless steel, when combined with iron, nickel, or manganese, forms an alloy with a low magnetic permeability. This characteristic ensures that the stainless steel, including SUS305, does not easily become magnetized when exposed to a magnetic field. It is worth noting that certain stainless steels remain entirely non-magnetic even at high temperatures, while other metals, like iron, would become significantly magnetized due to their ferromagnetic nature.

Chromium is also a crucial element in ensuring that stainless steel does not possess magnetic properties. By combining chromium with iron, nickel, or manganese, an alloy is formed with a low magnetic permeability. This means that the stainless steel does not readily become magnetized when subjected to a magnetic field. In fact, certain types of stainless steel remain non-magnetic even at elevated temperatures, unlike other metals that exhibit magnetism due to their ferromagnetic characteristics, such as iron.

Stainless steel 305 also includes small quantities of carbon, which plays a role in further reducing its magnetic properties. The presence of carbon creates areas of weakness within the alloy, causing disruptions in the flow of electrons and preventing them from aligning in a manner that would generate permanent magnets. As a result, although certain stainless steels may exhibit slight magnetization under extreme circumstances (such as very high temperatures), they promptly lose their magnetism once those conditions are eliminated and the steel cools down again.

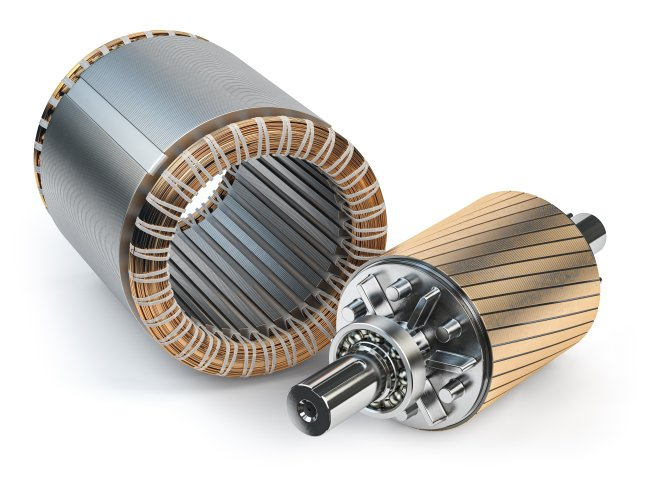

Due to its non-magnetic properties, SUS305 is used in communication equipment components and medical devices that require non-magnetic materials. It also finds applications in mechanical components used in conjunction with magnets. In particular, in motor components used in electric vehicles and other applications, SUS305 is commonly chosen because of its high strength, inability to be magnetized by the motor's magnet, and its minimal impact on the motor's rotational performance.