Sitting in the Millennium Park in Chicago, Cloud Gate, better known as The Bean, is an absolute stainless steel leviathan, 66 feet long, 33 feet high, 42 feet wide, and 110 tons in weight.

"What I wanted to do was to make a work that would deal with the incredible skyline of Chicago and the open sky and the lake but then also be a kind of gate. "

-- Anish Kapoor

-- Anish Kapoor

How the stainless steel bean was constructed? You can imagine it through these numbers. The plan started in 1999, which was a computer simulation, and to 2005, The Bean was born. With a span of 6 years, it was long, arduous and expensive, way more expensive than it was budgeted. It was estimated to cost $6 million but the final total cost was up to $23 million. No wonder it has been a startup and never fallen since the day it firstly unveiled itself in Millennium Park. The Bean has been second to no one. It is the hottest attraction in Chicago. The movie, The Break-Up, re-filmed some of the scenes in the park, just for counting The Bean in.

The masterpiece of Anish Kapoor was not the only master in the park. There was another project of a 150 feet tall, made of glass and stainless steel sculpture designed by Jeff Koons, but at last, the committee that included patrons of the arts and representatives of the Art Institution favored and insisted Kapoor’s work, so The Bean won its place and was moved to the center of the park.

Cloud Gate brings fame to Millennium Park, but how it was brought to the garden?

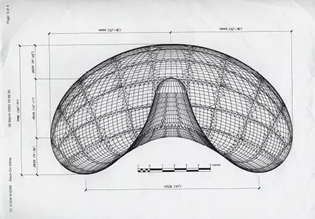

From a computer simulation to a wooden model, assisted by Ethan Silva who studied physics and art, he made out a sample of about 800 pounds welded by 4 pieces. The Bean became closer to what we see today. Before it was structured, Silva and Kapoor were in a seesaw game with The Bean pieces. Silva and his team carved out pieces by using a computer-controlled milling machine and sent the pieces to Kapoor who was in England, Kapoor looked them over and made recommendations for changes. This process lasted for 6 months. At the same time, Silva was evolving a computer model that calculated that it had to be divided into 168 plates to form Cloud Gate.

See how big a piece is!

It was an undertaking part when it comes to installation. Each piece of plates is in 3.8 inches thickness, and different in weight. The biggest one was 2m by 3m and 2 tons. Each plate is about 98 percent polished and covered with a protective coating when it arrives. However, all were refinished because of the many 3 to 5 inch seams in places where they were welded. To avoid compress between plates, every plate was hung separately on the turn-buckle on the frame. Hanging, welding, grinding, and polishing were proceeding in parallel.

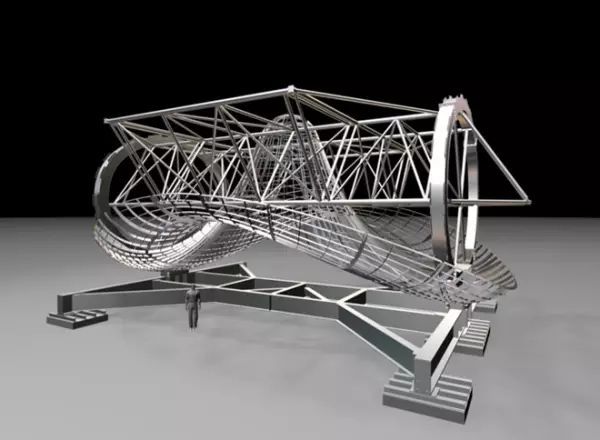

Frame simulation

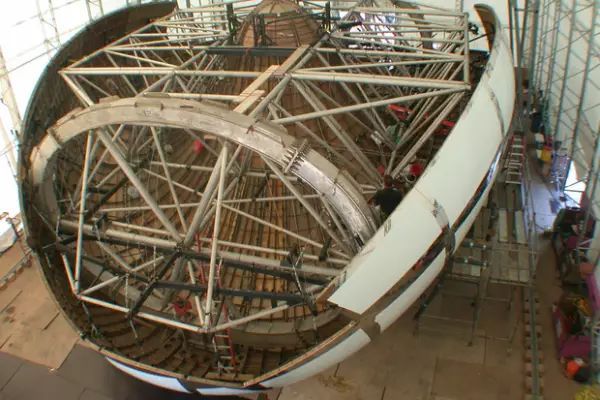

Frame costruction

The plates had to be perfectly shaped and machined to exact thickness tolerance. Inside this round bean, there needed trusses to hold it. There were two immense rings on both sides of the trusses, supported by a sub-base of I-beam set in concrete. Many plates forming the underside of the sculpture were bolted to temporary rigging attached to the trusses. Each plate was adjusted to form a smooth, continuous surface with the others. Seams were then be welded, ground and polished.

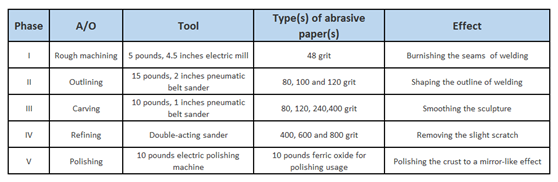

Every plate of Cloud Gate must be manufactured through 5 phases.

Omphalos

The top of The Bean

To install such huge plates, balance was a significant factor to ensure the stabilization, so the team used spring suspension. Also, the plates were installed in the opposite order and worked on simultaneously almost. For example, the first section installed is called omphalos, made of five plates, placing at 6 o’clock and the second part should be the one at 12 o’clock. As some plates were being made, others were being hung.

Welders on the trusses

Polishing

To weld The Bean, trusses were built outside of the sculpture. It was a huge challenge for workers to weld this eggshell which was composed of different shapes of plates in height, and also the shell is thin because it is contiguous, smooth, and strong. "The shape of the plates stems from the shape of the sculpture and also from anticipating the stresses induced by welding. Every place you weld, it shrinks, so you want the shrinkages to be in sort of a rhythmic pattern around the shape to give it a nice quality", Silva said.

The half-made Bean

In 2007, Cloud Gate won the industry outstanding achievement award of the American Welding Association.

People walking through omphalos, taking pictures, leaving memories, their imagination has come true when they were thinking while installing the first section. Now, The Bean is the real master in Millennium Park.